Home / About Rolawn / Rolawn’s history

From selling just over 2,000 metres of turf in 1975 to several million annually these days, Rolawn is recognised as Europe’s largest producer of cultivated turf and as Britain’s leading supplier of high-quality sustainable soft landscaping products. The Rolawn brand is the industry benchmark for quality and service, achieved through a commitment to advanced production processes, innovation and attention to detail in all areas for almost 50 years.

In the early 1970s, high-quality, ready-made natural turf was scarce; supplies were dwindling and there was no artificial alternative. Fortunately, at about the same time, a man called Leslie Dawson had a ‘lightbulb’ moment while turning out a box of overgrown cabbage plants. He noticed the tangled mess of roots and soil stuck to the underside of the plants and thought, ‘if you can do that with cabbage plants, why not try it with grass?’

Leslie was no green shoot – an Agronomist by trade and Head of Seed Development at Scottish Agricultural Industries – he knew a thing or two about grass and in 1975, Rolawn (Turf Growers) Ltd was founded with Leslie’s son, Kenneth Dawson, at the helm.

The company started life in Aberdeen and started growing turf under controlled conditions with the aim of producing high-quality, ‘no-waiting’ grass to meet the demand generated by the expansion of leisure activities, the increase in golf courses and the growing requirement for quality grass for landscaping and amenity purposes.

The first year was very busy; rigorous testing was undertaken, processes were refined and agricultural methods and machinery were implemented to achieve high-quality, sustainable turf production. Half an acre of turf was produced and the first order was received from the village blacksmith, who wanted three square yards! When cut, Rolawn’s turf was a fraction of the thickness and weight of conventional turf but crucially, retained the grass rooting system complete, uncut and ready to root. It was ready to mow within two weeks of laying and the choice of seed mix ensured a consistent sward of fine grasses with no coarse grass or weeds.

In 1976, the company moved south to the Vale of York, following the results of a commissioned soil survey which highlighted the area as the UK’s ‘soil supercentre’ for turf growing, borrowed £1,800 and bought an eight-acre field in front of Elvington Hall. By autumn, stocks of turf were sold out.

In 1978, the All England Club’s Head Groundsman, Jack Yardley, ordered Rolawn turf for Wimbledon’s four new grass courts. In September 1978, he allowed three short sessions to be played on the courts and announced himself ‘absolutely delighted’ with them. The courts opened for The Championships nine months later on 23rd June 1980 – at 2pm precisely.

In the early 1980s, Rolawn made the decision to start to cater for the domestic, landscaping and building markets – different grades were grown for these applications, but the quality remained high with the turf still maintained for up to two years before being harvested to order.

During this time, Rolawn was also awarded a £1million contract for landscaping works at the Queen Alia International Airport in Jordan, supplied 11,000 square yards of turf to a revolutionary new pitch at Fulham Football Ground – which was played on within one month of being laid – supplied all turf for the Meadowbank Stadium for the Commonwealth Games in 1986, fulfilled its largest single order to date for 70,000 square yards of turf to the Glasgow Garden Festival and Kenneth Dawson was elected Chairman of the International Representatives Committee of ASPA (American Sod Producers Association) – the first Briton to be elected Chairman to any of its committees.

By the mid-1980s, the company that started with half an acre of turf was now the largest turf grower in Europe with over 1,000 acres under cultivation in four areas of Britain.

The rest of the 80s were no less busy with Rolawn developing a UK first in the form of cultivated ‘Washed Turf’. The company developed a machine that washed off the soil from the turf and because of the remarkable strength of the turf’s root system, the grass didn’t fall apart under its own weight. One of the first orders for washed turf was from Queens Park Rangers, which ordered 9,000 square yards to replace its existing artificial turf pitch.

Rolawn also satisfied some rather more quirky orders during the 1980s. In 1982, an emergency supply of 780 square yards of turf was rushed to Vienna to meet the demands of a German ballet star, who threatened to walk out of the Pans 82 Festival in Vienna unless the organisers laid ‘real turf’ for her – the ground within a 1,000 km radius of the city was frozen solid! Rolawn turf made its UK theatrical debut at Newcastle’s Theatre Royal where it was laid on stage for a run of Anton Chekhov’s play, ‘The Seagull’. The grass was watered daily …

By the end of the 1980s, Rolawn was selling some four million square yards per year. At the beginning of the 1990s, it was supplying cultivated turf at a rate equivalent to three soccer pitches per day and harvesting 2,000 square yards per hour. In 1991, plans were announced to double cultivated turf production to around 3,000 acres per year.

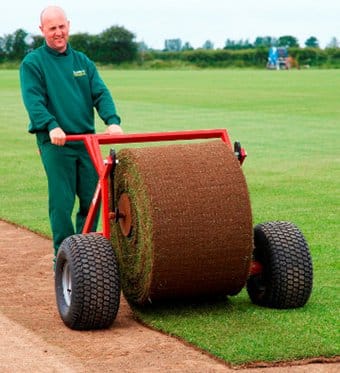

In 1993, Rolawn launched its new ‘Turfmaster®’ machine – designed and built in-house to enable rapid laying of large volumes of turf. Turfmaster laying trolleys were supplied on free loan to contractors and are still very much a part of the product range today.

Orders fulfilled during the 1990s included 3,000 square yards to Stonehenge, 480 square yards of turf to the Japanese Embassy in London, 10,000 square yards to Chelsea and Leeds football clubs for their brand new pitches, 2,000 square yards every year for Epsom’s Derby parade ring and 3,500 square yards to repair Rod Stewart’s private football pitch.

1995 saw the end of the square yard within Rolawn and introduction of the square metre as UK regulations changed to require packaged goods sold in Britain to be labelled in metric units.

In 1997, Rolawn made its European business debut and supplied the brand new Dutch ‘Ajax’ club pitch with seven loads of turf transported from York to Amsterdam.

The start of the new millennium saw two very significant developments for Rolawn; firstly, joining the online revolution with the launch of www.rolawn.co.uk. Since this initial launch, Rolawn websites have revolutionised accessibility to information regarding turf and topsoil, with sophisticated methods for researching lawn maintenance techniques and technical specifications. The second development was Rolawn’s entry into the high-quality topsoil market. Ever-increasing customer demand for high-quality products resulted in Rolawn being the first company of its kind to supply soft landscaping products in bulk bags – a far more convenient supply method for customers. Rolawn is now recognised as Britain’s leading supplier of high-quality topsoils, barks and mulches.

The noughties were a busy decade for Rolawn’s in-house design team which developed and built a revolutionary and unique machine – the mighty 21-gang mower. This behemoth of a machine was three times the size of industry standard machines and for a company that spends a lot of time and money mowing turf, brought major benefits. One machine and one person could do the work of three and just as importantly, one machine left only one footprint which meant that the impact on the land was greatly reduced. Ten of these machines were subsequently built by Rolawn’s engineers to cope with mowing thousands of acres of turf daily. To support the topsoil side of the business, the in-house team also designed and built Rolawn’s own bagging plant and towards the end of the decade, they launched a bespoke, cultivated turf seed drill.

Rolawn also invested heavily in machinery and premises during this time. Two new state-of-the-art harvesters were brought in as well as irrigators and a massive sprayer. The sprayer was one of the largest available in Europe – when opened, it was 48 metres wide and able to spray 500 acres per day! In addition, Rolawn purchased a 21-acre site at Seaton Ross, Yorkshire in 2006 which became the company’s main bulk products facility and a year later, a second site in Seaton Ross was purchased.

In 2005, Kenneth Dawson was awarded the American-based ‘TPI’ (Turfgrass Producers International) ‘Honorary Member Award’, acknowledging him as the ‘first pioneer of cultivated turf production in the UK’. High praise indeed – the TPI is a global organisation committed to the advancement of the turf grass industry and is recognised throughout the world as the most respected and prestigious body of its kind.

In 2010, Rolawn acquired recycling business Hallstone Developments Ltd. This key acquisition gives Rolawn access to and control of composts which are a vital component in the production of the company’s topsoil not to mention an additional 13-acre site to allow for future business expansion.

2011 saw the introduction of Rolawn’s Profresh® System – a unique, patented and trademarked system which highlights Rolawn’s commitment to innovation. The technology extends the shelf life of turf by up to three times, giving stockists the advantage of selling the product in optimum condition and customers greater access to fresh turf.

In the future, this technology will allow Rolawn to package both full pallets and individual pieces of turf, if required, giving greater traceability and quality control and allowing sell-by dates, barcodes and branding to be included.

Almost 50 years on from Leslie Dawson drawing inspiration from some cabbage roots, Rolawn is going from strength to strength. The further development of Profresh technology and greater automation within turf production promises to keep Rolawn at the head of the industry for many years to come.